The Zortström technology

Multivalent energy utilisation, precise storage concept, hydraulic decoupling and exact temperature separation: the efficiency building blocks of Zortström technology

The Zortström technology, which has been tried and tested for many years, is used in over 7,000 heating and cooling systems throughout Europe. Its success is based on four fundamental processes that are combined in one system: the decoupling of all volume flows, precise temperature separation, integrated buffer and distribution function and precise output adjustment to generator and consumer requirements.

The patented Zortström technology combines in every Zortea product the functions of a hydraulic separator, a manifold and a buffer tank with precise separation into any number of temperature layers.

The reliable decoupling of all volume flows of the generators and consumers prevents mutual interference and overlapping. Pumps and valves can operate trouble-free and with minimised power consumption. Thanks to precise temperature separation using the patented flow split units, no unwanted mixing occurs, even with fluctuating and different volume flows, so that the generators only have to supply the energy that is actually required and the consumers always have the desired temperature available. The patented sliding layer space as a buffer volume between the respective temperature layers also allows the runtime optimisation of combined heat and power plants, heat pumps or chillers, as well as the short-term coverage of peak loads. Minimised volume flows enable the desired low return temperatures and thus improve the efficiency of the overall system.

A Zortström product not only acts as the hydraulic zero point of the system, but also as a volume flow, temperature and energy manager. This also opens up the possibility of returning the often unused waste heat to the system and utilising it sensibly.

The Zortström provides and supplies thermal energy in line with demand and with maximum precision on both the generator and consumer side. Measurements by Fraunhofer ISE in Duisburg confirm that the power consumption of state-of-the-art speed-controlled pumps is reduced by up to 80 per cent. This makes Zortström one of the most economically and ecologically effective technologies for safe and efficient system operation.

Functionality

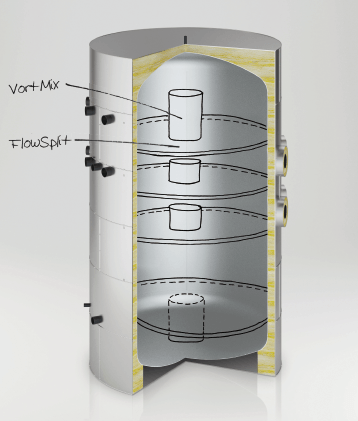

- due to the dynamics of the water, the patented VortMix mixes incoming and outgoing volume flows and guarantees a homogeneous temperature in each stage

- the consumers and producers are integrated with flow and return in the corresponding temperature layer

- the consumer pumps get the energy they need at the right temperature without resistance

- temperature sensors are fitted at each temperature level

- the heat generators are switched on and off independently of each other via the setpoint temperatures for each stage

- the FlowSplit unit ensures temperature separation and volume flow from layer to layer

The VortMix immediately mixes the incoming water with the water in the stage. This ensures that the temperature in the stage is absolutely homogeneous and that all consumers receive the same temperature. The VortMix utilises the dynamics of the water, so we have the option of flowing in at high speed, up to 5 m per second!

FlowSplit ensures the reliable separation of the temperature layers and the flow-controlled exchange of water between the stages. The FlowSplit also loads and unloads the sliding layer chamber in such a way that the target temperature in the sliding layer chamber is shifted up or down and the volume is not mixed.